Notizie per Categorie

Articoli Recenti

- [Launched] Generally Available: Migrate Azure VM backups from standard to enhanced policy 11 Luglio 2025

- Forrester names Microsoft a Leader in the 2025 Zero Trust Platforms Wave™ report 10 Luglio 2025

- [Launched] Generally Available: Azure Automation supports PowerShell 7.4 & Python 3.10 runbooks and Runtime environment 10 Luglio 2025

- [In development] Private Preview: Enable Trusted launch on existing Virtual machine Flex scale set 10 Luglio 2025

- [Launched] Generally Available: Enable Trusted launch on existing Virtual machine Uniform scale set 10 Luglio 2025

- [In preview] Public Preview: Trusted launch default for new Gen2 VMs & Scale sets 10 Luglio 2025

- [Launched] Generally Available: Granular Role-Based Access Control (RBAC) for Azure File Sync 10 Luglio 2025

- [Launched] Generally Available: Customer controlled maintenance for Azure Firewall 9 Luglio 2025

- Microsoft expands Zero Trust workshop to cover network, SecOps, and more 9 Luglio 2025

- Enhancing Microsoft 365 security by eliminating high-privilege access 8 Luglio 2025

Microsoft experience at Hannover Messe 2024: Accelerating industrial transformation with AI

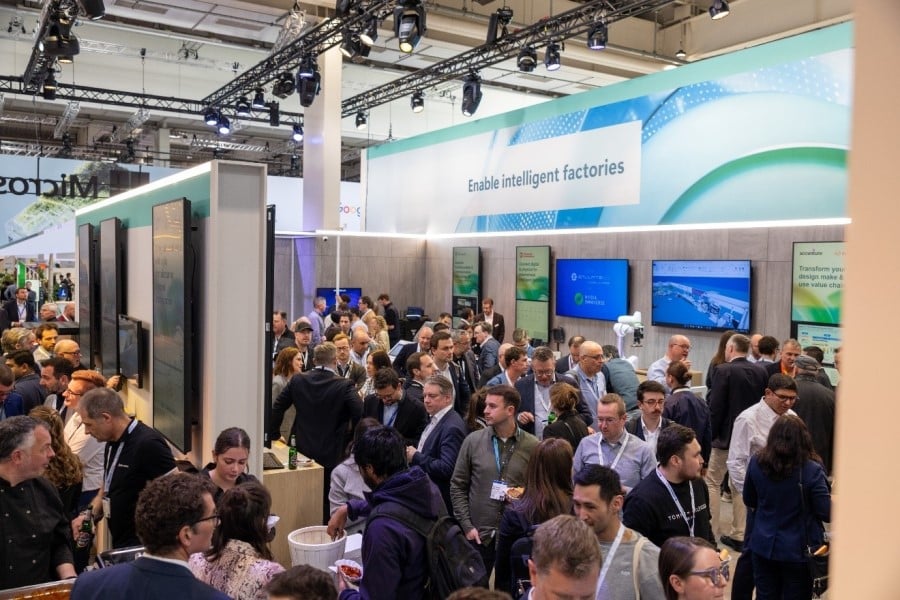

With nearly 130,000 global business and government leaders in attendance, Hannover Messe is the event to showcase innovation in the manufacturing industry. This year, together with our partners and customers, Microsoft showed how our technology is enabling manufacturers to “Accelerate Industrial Transformation with AI.” With almost 40 demonstrations of technology and 30 speaking sessions, we showed how manufacturers can transform their entire value chain from product design to post-sales service with Microsoft technologies. To support customers along their transformation journey, we announced several new innovations, including the new manufacturing data solutions in Microsoft Fabric (preview) and the Copilot template for factory operations on Microsoft Azure AI, new Copilot capabilities in Dynamics 365 Field Service, and improved traceability in Dynamics 365 Supply Chain Management, all of which attendees had the opportunity to experience first-hand at the booth.

Ahead of the fair, we also published a new report in collaboration with MIT Technology Review Insights uncovering the current state and ambitions around AI in the manufacturing industry. The report clearly indicates that manufacturers are excited about the potential of AI and plan to make significant investments over the next two to three years to deploy AI at scale to unlock innovation and enhance efficiency.

Transforming the manufacturing value chain with AI

The Microsoft experience focused on how AI transforms the manufacturing value chain: starting with accelerating product development cycles, improving efficiency in the factory, making operations more sustainable, and finally empowering every employee across business functions with the latest AI tools. These four opportunities manifested as the four distinct neighborhoods in the booth, with demos and customer stories populating each one.

1. Unlock innovation in design and engineering

AI has the potential to unlock a tremendous amount of innovation in design and engineering by allowing manufacturers to simulate and generate new options faster. It can help accelerate development cycles for new products and services as shown by our customers Kuka & Schneider Electric, how manufacturers can accelerate the programming of industrial robots and programmable logic controllers (PLCs) with Microsoft Azure OpenAI Service, significantly speeding up development times. Siemens, along with customer Harting, showcased how generative AI can be used to speed up the design process of new industrial connectors and revolutionize mass-customization. Additionally, our partners Threedy, PTC, Hexagon, Capgemini, and Ansys showcased how applying technologies from digital twins to mixed reality to the Internet of Things (IoT) and cloud computing accelerates product development cycles.

2. Enable intelligent factories

Making factories smarter is top of mind for manufacturers. In this area of the booth, we showed customers how they can improve quality, resource utilization and accelerate issue resolution in the factory with industrial IoT, data, and AI. Along with our partners Accenture, Avanade, Sight Machine, Rockwell, and AVEVA, we showcased the manufacturing data solutions in Fabric (preview) and the Copilot template for factory operations on Azure AI. These solutions help manufacturers unify their information technology (IT) and operational technology (OT) data estates in an industry standard data model on Fabric. The Copilot template then uses this unified data to answer questions asked in natural language to help resolve issues on the factory floor. In addition, we showcased solutions from partners such as Tulip, TCS, SymphonyAI, SAP with Syntax, Cognite, Weavix, and Unmanned Life and from customers including Andritz, Chevron, Electrolux, and Ecopetrol that utilize Microsoft Azure IoT Operations, Azure private multi-access edge compute (MEC), Azure AI, Fabric, and more to enable intelligent factories.

3. Create resilient and sustainable operations

Manufacturing companies are looking to make their supply chain and service operations more resilient and sustainable. In this neighborhood we showed how they can achieve their goals using the power of cloud, AI, and mixed reality. In collaboration with Volvo Penta, we showed how using Microsoft Copilot in Dynamics 365 Field Service and Guides improves technician training, service manager workflows, and eventually, delivers better customer outcomes for their marine engines. With Caterpillar, we showcased how their Service Information System built on Azure provides detailed service information for CAT products from 1977 up to today. We also showcased Microsoft Sustainability Manager, which helps organizations to record, report, and reduce their environmental impacts through the power of data and AI. Our partners Blue Yonder, O9, and Tools Group demonstrated the power of cloud and AI to make supply chains more resilient.

4. Enhance employee productivity with AI

AI has the potential to unlock productivity and innovation for employees in all areas of the business. In this area of the booth, we showcased how Microsoft Copilot in products such as Microsoft Teams, Microsoft Security, Microsoft Power Platform, Fabric, Microsoft Dynamics 365, Windows, and Bing on Surface devices can empower employees across business functions in the manufacturing enterprise to achieve more. We showcased how Microsoft Copilot for Security and Microsoft Defender for IoT empower security teams to protect their OT environments, bringing collaboration to the forefront by reducing knowledge barriers for securing such environments. In the Fabric demo, we showed how manufacturing customers can use the suite of analytics workloads in Fabric, Copilot in Fabric, and direct integration with generative AI models to transform their factory operations.

The BMW Group showcase was the connecting thread between each of the booth neighborhoods. Built in collaboration with Hexagon, NVIDIA, PTC, and Rockwell Automation, business leaders and dignitaries could experience how technology enables cutting-edge transformation through AI-assisted design, connected data, and agile production for organizations like BMW Group. Featured in the exclusive Hannover Messe press tour highlight, which hosted more than 40 international journalists, this demo garnered significant attention for depicting how the integration of technology is changing manufacturing as we know it.

Thought leadership and continued innovation

A space for thought leadership, the Microsoft theater was very busy this year, bringing together C-level leaders, innovators, and business leaders eager to learn about how technology is changing the sector, what their peers are doing, and the importance of diversity within manufacturing. This space connected customers to the experts: creating a unique forum of innovation where solutions to complex industrial problems were revealed, and where ideas were brought to life.

Covering topics from the return on investment (ROI) of 5G factories, to delivering practical insights for how exactly to build your own copilots, the theater sessions delivered valuable insights on the most pressing questions the industry faces today. Here are a few highlights of the theater sessions:

- Celebrating women in manufacturing brought together influential voices of women in manufacturing to explore their career journeys, achievements, challenges, and best leadership practices to inspire the next generation of female talent.

- Industrial transformation with AI: A discussion with Kraft and Schneider Electric shared how cloud, IoT, and mixed reality technologies together with AI are reshaping entire value chains.

- Microsoft partners, including IBM, PwC, Fractal, DXC, Honeywell, and Rescale spoke about how their solutions built with Microsoft technologies can help transform all aspects of manufacturing from design and engineering to the factory floor.

- Microsoft Intelligent Manufacturing Award showcase, in partnership with Roland Berger, celebrated the winners of the fifth annual Microsoft Intelligent Manufacturing Awards (MIMA), a prestigious award recognizing innovation in digitalizing the manufacturing industry in Europe, Middle East, and Africa (EMEA). The award honors the most promising and innovative digital best practices from the industrial and operations sectors: production, purchasing, supply chain, engineering, and after sales. This year’s MIMA winners were Mercedes Benz, Northvolt, Malvern Paralytical, Wilo, Andritz, and Danfoss.

Learn more about solutions from Microsoft

Finally, we would like to thank our customers and partners who joined us at the booth as exhibitors, along with the thousands of attendees who visited the booth to engage with us and looking forward to Hannover Messe 2025. To learn more about the latest solutions for manufacturing, please visit Microsoft Cloud for Manufacturing.

The post Microsoft experience at Hannover Messe 2024: Accelerating industrial transformation with AI appeared first on Microsoft Industry Blogs.

Source: Microsoft Industry Blog